Composite Systems

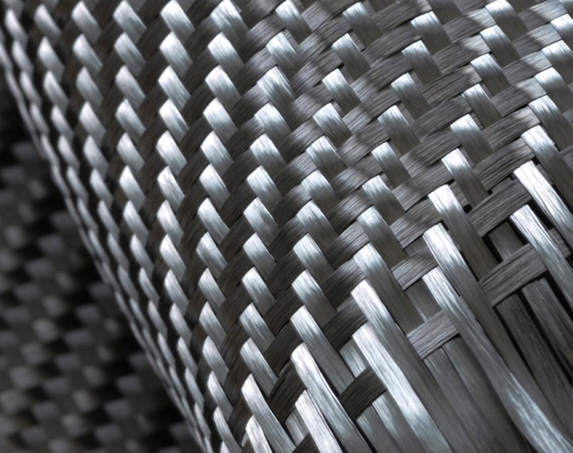

Advanced FRP CF 300-BD SAT 200 – Medium-weight, bi-directional, high-strength carbon fiber composite cured with FRP 200 Saturant for repairs on small pipes, nozzles, etc.

Advanced FRP CF 500-BD SAT200 – Heavy-weight, bi-directional, aerospace grade, high tensile strength carbon fiber composite cured with FRP 200 Saturant.

Advanced FRP CFL 1000 – High-strength, high-modulus, pre-cured carbon fiber laminate strip designed to provide structural reinforcement for steel, concrete, timber, and masonry structures.

Advanced FRP GF 300-BD SAT 200 – Bi-directional glass fiber composite cured with FRP 200 Saturant provides excellent insulation for heat and electricity.

Advanced FRP GF 130 MCU – Pre-impregnated, moisture-cured, bi-directional fiberglass composite system designed for repairs of active leaks from cracks, corrosion and joint failures.

Advanced FRP SAT 200 – Zero VOC, epoxy saturating resin for ambient temperature services. Designed for outstanding resistance to water, caustics, and other aqueous materials.

Advanced FRP SAT 220 C – Chemically resistant composite saturating resin designed to impregnate carbon, glass, or Kevlar fibers and withstand solvents like acetone, dichloromethane, toluene, and methanol.

Advanced FRP KF 600-BD SAT 200 – Heavy-weight, bi-directional Kevlar fiber composite cured with FRP 200 saturant provides outstanding impact resistance.

High-Temperature Composites

Advanced FRP 120 HT– High-strength adhesive provides over 4,000 psi adhesion to blasted steel. Designed for service up to 275°F.

Advanced FRP CF 500-BD SAT210 HT – Heavy-weight, bi-directional, aerospace-grade, high-tensile strength carbon fiber composite cured with FRP 210 HT Saturant for high-temperature services.

Advanced FRP SAT 210 HT – Zero VOC, epoxy saturating resin for elevated temperature services up to 375°F. Creates high strength, corrosion resistant composites with fiberglass, carbon fiber and Kevlar.

Advanced FRP Tack Coat 110 HT – Epoxy adhesive coat designed for application of composites on vertical and overhead surfaces.

High-Build Coatings

Advanced FRP EM-110 – High-strength, reinforced epoxy mortar designed for patch repairs on concrete engineered for chemical, abrasion, and impact resistance. Aggregate loading can be varied to achieve desired consistency.

Advanced FRP Repair Putty HT– High-build epoxy putty system used to fill in cracks, cover welds and resurface badly corroded substrates for elevated temperature service.

Advanced FRP Repair Putty– High-build epoxy putty system designed to resurface badly corroded substrates and shape surfaces for composite reinforcement.

Advanced FRP SL-310 Fast – Fast-curing, thick-film structural lining system engineered to rebuild and reinforce badly damaged concrete and steel, providing structural reinforcement and long-term corrosion resistance even in immersion services. Designed for plural component spray application.

Advanced FRP SL-310 – Thick-film, spray-applied structural lining, our most economical structural reinforcement.

Advanced FRP Ceramic Repair Putty HT – 2-part epoxy putty system with an engineered blend of ceramic particles designed to handle thermal cycling and high-temperature abrasion.

Advanced FRP Ceramic Repair Putty MT – 2-part epoxy putty system with an engineered blend of ceramic particles formulated with a hydrophilic resin to provide adhesion to damp surfaces and curing in underwater conditions.

Advanced FRP Ceramic Repair Putty – 2-part epoxy putty system with an engineered blend of ceramic particles designed to provide excellent abrasion and chemical resistance.

Immersion-Grade Coatings

Advanced FRP HP-300 AR – Immersion-grade epoxy coating system designed with an engineered blend of ceramic particles for excellent abrasion resistance.

Advanced FRP HP-300 Elastomer – Immersion-grade epoxy lining system designed for applications requiring high elongation or flexibility such as concrete coatings, cooling tower basins, or areas with high levels of cavitation.

Advanced FRP HP-300 GF – Immersion-grade epoxy coating system reinforced with Glass flakes to enhance permeation resistance for aggressive immersion conditions.

Advanced FRP HP-300 LSE – Immersion-grade epoxy coating with an engineered blend of ceramic particles for excellent abrasion resistance. Modified with a unique surface additive to provide long lasting water repellency.

Advanced FRP HP-300 – Immersion-grade epoxy coating system designed to provide outstanding resistance to a wide-range of exposure conditions on metal, composite or concrete applications.

Advanced FRP HP-400 AR – Chemically resistant, epoxy novolac coating system designed with an engineered blend of ceramic particles for excellent abrasion resistance even in application with aggressive chemicals or elevated temperatures.

Advanced FRP HP-400 Novo – Epoxy novolac coating system engineered for exceptional resistance to chemical attack from immersion in strong mineral acids and caustics.

Advanced FRP HP-410 GF – Glass flake reinforced epoxy novolac coating system with outstanding barrier properties and elevated temperature resistance. Designed for immersion in areas prone to osmotic blistering.

Advanced FRP HP-410 Novo – Chemically resistant, epoxy novolac coating system designed for long term immersion in aggressive solvents and hydrocarbons.

Specialty Coating Systems

Advanced FRP 200 Sealer – High-strength adhesive engineered to provide over 750 psi adhesion to concrete and reduce pinholes caused by outgassing from concrete.

Advanced FRP 201 OT Primer – 100% solids epoxy primer engineered to provide outstanding adhesion even to oil contaminated surfaces.

Advanced FRP HDF 250 – A heavy-duty, 100% solids epoxy industrial floor coating system engineered to provide excellent chemical, abrasion, and impact resistance in an easy-to-use, surface-tolerant formulation.

Advanced FRP HP-300 UV – A color stable coating system for composites and structural steel, suitable for even the harshest atmospheric corrosion conditions.

Having Issues with Pipe Corrosion or Erosion?

Contact us for a free evaluation!

X