Tank Repair for Power Generating Plants

Water Treatment Tanks

Demineralization units are critical components of thermal power generation facilities. Often requiring both strong acids and strong bases, these systems are very aggressive towards most coatings, composites, steel, and concrete. We design proven solutions for every part of your water treatment process, including materials that are compatible with immersion in 98% sulfuric acid and neutralization basins. Allow our team to help protect your tanks, pumps, pipes, and secondary containment.

Scrubber Vessels

A typical Flue-gas desulfurization (FGD) system has a highly corrosive environment, causing rapid corrosion of unprotected steel. Scrubber vessels are exposed to hot, acidic gases and caustic slurries. Vinyl esters coatings, epoxy coatings, thermal spray, and even expensive stainless alloys can fail in the extreme conditions of a scrubber vessel. Ask an expert about versatile, high strength, chemically resistant composite reinforcement options for both wet and dry scrubbers.

Lime/Limestone Slurry Tanks

Flue gas desulfurization systems require a constant supply of lime or limestone to continue to remove sulfur. Tanks containing lime and limestone can be very aggressive, especially if they are agitated. Advanced FRP offers a wide range of solutions ranging from abrasion-resistant composites to fully structural reinforcement for even the most severely damaged tanks. Our experts can help diagnose issues with corrosion and erosion and prescribe the best, customized solution for your facility.

Clarifiers

Clarifier tanks, rakes, and spillover trays are critical components to many processes, from power generation to wastewater processing. Repair options are available for every part of your clarifier, often providing a 50-year, maintenance-free life extension for your clarifier. Our customized solutions allow you to fix only the areas that need to be repaired and are fully compatible with a wide range of protective coatings systems. Talk to an expert now to see if we can help you.

Fuel Storage Tanks

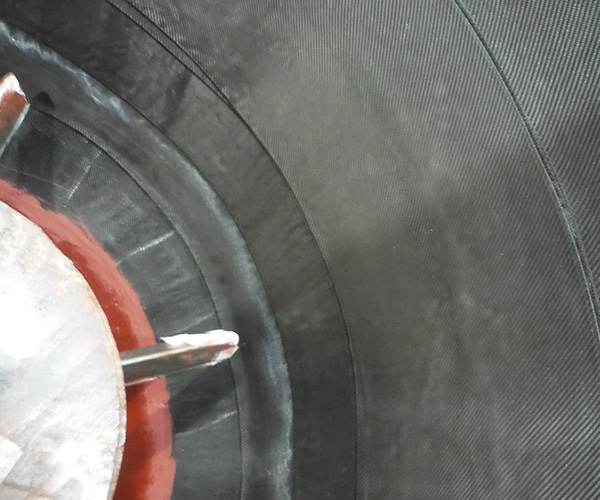

Fuel oil, diesel, gasoline, and other hydrocarbon storage tanks are critical for the operation of many power generation facilities. Tanks that are storing hydrocarbons, especially if they are not used frequently, are very prone to corrosion at the floor to wall joint. Corrosion occurs because of trace water content in your hydrocarbon fuel. Composite reinforcement solutions will not only prevent further corrosion but will structurally reinforce the floor and floor to wall joint to ensure continued operation of your tank.

Condensate Tanks

Immersion service in the condensate is very aggressive towards most industrial coatings, so many condensate tanks are simply not coated. Both stainless steel and aluminum tanks do not corrode quickly in pure water. However, microbially induced corrosion (MIC) is common in condensate tanks around the world. If you see coating blisters or worm-hole type corrosion, contact Advanced FRP experts to help you diagnose your problem and specify a long-term repair solution.

Ask Advanced FRP

Search for the solution you’re looking for, and we’ll provide you with the answer.

Having issues with tank corrosion or erosion?

Contact us for a free evaluation

X