Construction companies are increasingly using composites like carbon fiber and glass-reinforced plastic or epoxy injection to provide external confinement for damaged and weak concrete core when the capacity of the existing column is inadequate. These techniques provide an additional advantage of stopping further degradation of corroded reinforcing steel.

More-

How to Repair Concrete Columns with Carbon Fiber Composites

-

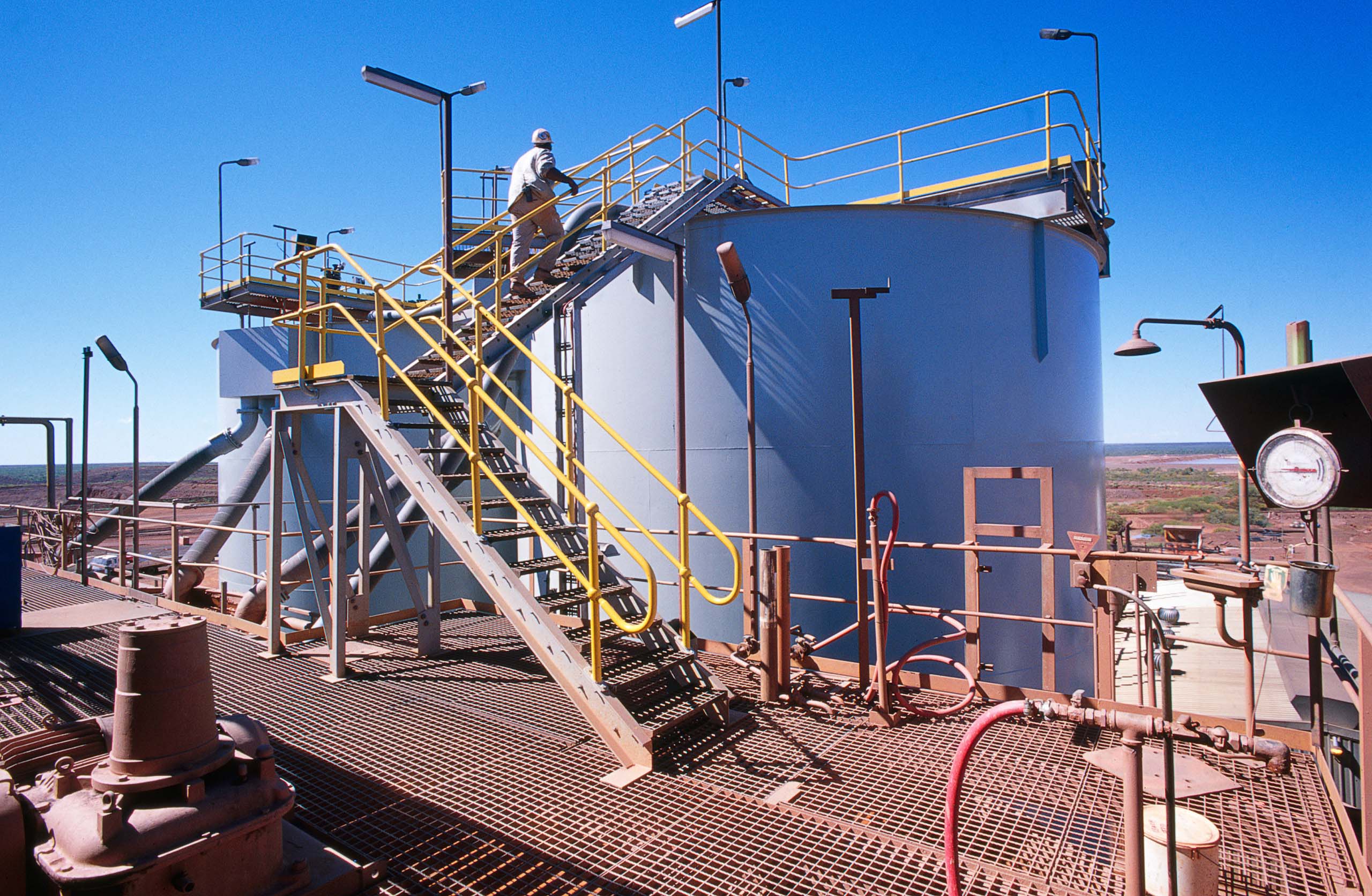

Carbon Fiber Composite Tank Repairs

Offering a combination of strength and longevity, Carbon fiber based composites are becoming a popular technology for repairing industrial tanks. Advanced FRP Systems has a wide range of corrosion prevention and structural rehabilitation solutions utilizing carbon fiber composites. Because of carbon fiber’s ability to fit a variety of shapes, it can be used to repair [...] More -

Solutions for Pipe Damage Caused by Acoustic-Induced Vibration

Vibrations in piping systems can cause a myriad of issues ranging from equipment damage to fatigue failure. While there are some causes of vibration that are observable through normal operation and inspection, Acoustic-Induced Vibration (AIV) is different as it is caused by acoustic waves occurring at high frequencies. As these high-frequency sound waves travel through [...] More -

Carbon Fiber Solutions for Structural Repair and Reinforcement

Around the world, the degradation of infrastructure is a major challenge. The use of carbon fiber-based composite systems to protect and reinforce infrastructure has allowed for the repair of bridges, beams, and columns that otherwise would have to be replaced. Carbon fiber offers several distinct advantages over traditional materials like concrete, steel, or wood when it comes to structural reinforcement. Learn about the addressable areas and application of carbon fiber in infrastructure in our latest blog post.

More -

Online Composite Reinforcement of a Heat Exchanger Shell

Heat exchangers are a critical industrial component used to keep chemicals, water, gas, and other substances within a safe operating temperature. Damage to any of its components can pose significant risks to the facilities and workers that operate them. Read on to learn how Advanced FRP Systems helped a chemical manufacturer salvage one of their [...] More -

Composite Repairs in High-Temperature Environments

Updates of the code requirements along with the development of more robust Carbon Fiber Composite Repair Systems have allowed oil and gas refineries, chemical manufacturing plants and other industrial facilities to use these composite repairs on their critical piping systems. In the past, composites have only been used for circulating water lines and other low-risk [...] More -

The Complete Guide to Corrosion Management System

Advances in inspection techniques and corrosion mitigation technologies have changed the perception of corrosion in industrial settings from being inevitable to something that can and should be managed. However, even the best corrosion mitigation and inspection tools cannot fully alleviate the significant threat that corrosion poses to pipes, tanks, and other metallic structures around the [...] More -

Pipe Repair Methods: How to Repair Leaks in Critical Water Lines

In previous blog posts, we’ve spoken about how coatings can fail in industrial facilities, especially in water immersion conditions. This post will discuss the variety of options that an industrial plant has to repair leaks in critical water piping systems like circulating water lines, fire suppression lines, and service water lines. We will explore the [...] More -

Why Do Circulating Water Lines Fail?

Circulating water lines are pipes used in power generation facilities, chemical plants, oil refineries, and other heavy industrial applications. They differ in terms of design requirements but have common features and common reasons for failure. Today, repairs for circulating water lines can use several different methods. Each method has its place, which is why it’s [...] More -

Coating Failures in Water-Immersion Conditions: Poor Surface Preparation and Application

Along with Osmotic Blistering and Microbially Induced Corrosion, Poor Surface Preparation and Application is the third reason for a failure of industrial coatings in water-immersion conditions. In our previous blog posts, we explored Osmotic Blistering and MIC. This blog post explores common issues that can lead to poor surface preparation and application and how to [...] More