Carbon Fiber Pipe Repair and Reinforcement for Buried and Above Ground Pipes

Advanced FRP Systems specializes in long-lasting, maintenance-free repairs for industrial pipes. Our composite repairs can be used for spot repairs on leaking pipes or to completely rebuild your piping system with high strength, corrosion-resistant carbon fiber composite pipe. In many cases, repairs can be done while your process is still in service.

Composite pipe reinforcement is a fast, cost-effective alternative for pipe replacement. It provides a longer life expectancy than traditional pipe clamps, does not require hot work as welded solutions do, restores the full functional capacity of distressed, degraded, or damaged pipes, and increases system reliability and availability.

Before you consider replacing piping, reach out to our experts to see if composite pipe reinforcement is a better option for you.

Why Carbon Fiber Is The Right Choice

Using an engineered composite carbon fiber reinforcement system is a great alternative to pipe replacement. No matter how badly degraded your pipes may be, we can design a system to bring them back to or exceed their original values.

Carbon Fiber

- Is very light-weight and can withstand up to 1000 psi for pipes with through-wall failures and up to 3000 psi for pipes with less than or equal to 80% wall loss.

- Is corrosion resistant and can be designed to withstand concentrated acids or aggressive solvents.

- Bonds to a wide range of substrates, including carbon steel, aluminum, stainless steel, concrete, fiberglass, and even wood.

- Designed to withstand temperatures up to 375°F, making it suitable for high-temperature assets and assets that experience thermal cycling.

- Is compatible with abrasion-resistant ceramic-filled epoxy technology

Carbon fiber composites will act as a thick-film coating preventing further corrosion. The composites can be installed internally or externally, with many of the external applications occurring while your system is online.

All our products, including our carbon fiber threads, are made in the USA. We provide only the highest quality materials fully compliant with ASME PCC-2 (2015) for Long-Term Repairs Including Through-Wall Failures as well as many other pertinent ISO, ASTM, ASME, and API code requirements.

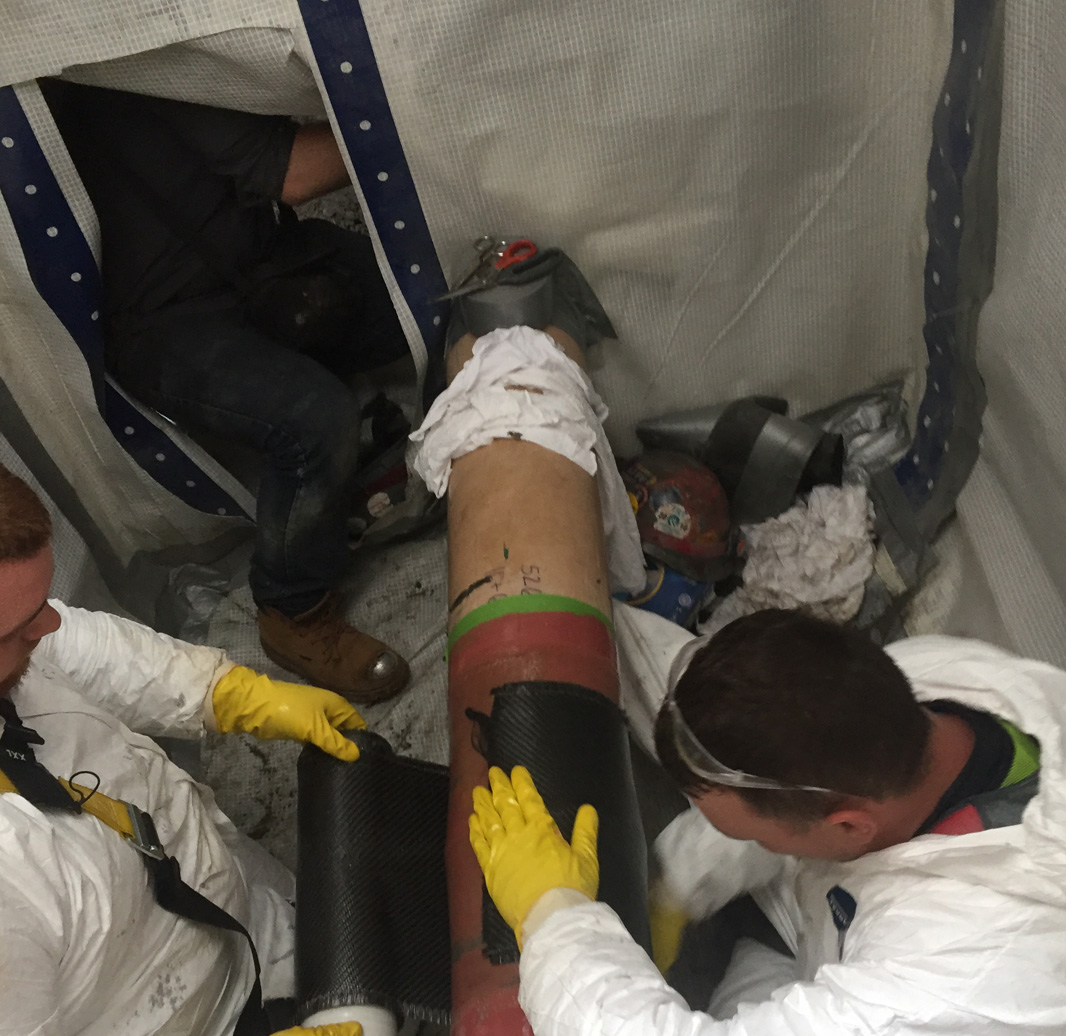

Carbon Fiber Installation Process

Most composite repairs require surface preparation of the entire pipe surface. Our adhesion zone concept can help reduce required surface preparation by up to 95%.

Our carbon fiber composite installation process includes:

- Surface preparation

- Active leak mitigation (when necessary)

- Filling in of pits and voids using a high-build, epoxy putty

- Installation of a galvanic barrier (when necessary)

- Application of a high-strength carbon fiber composite with your needs guiding the design of the repair.

- A wide-range high-performance functional coatings can be applied depending on the exposure conditions and design criteria of the carbon fiber composite.

All the system components are 100% solids, zero-VOC epoxy technologies and can be applied wet-on-wet, enabling some repairs to be completed within a single shift.

Industries We Serve

- Power Generation

- Power Transmission

- Oil & Gas

- Chemical Manufacturing

- Pulp & Paper

- Water & Wastewater

- Mining

Chemical Manufacturing

- Process Water Lines

- Fire Suppression Piping

- Chemical Pipes

- Chemical Waste Pipes

- Heat Exchanger Shells

Oil & Gas

- Crude Oil Piping

- Refined Product Piping

- Horizontal Directional Drilled Pipes

- Wastewater Piping and Fracking Fluids

Pulp & Paper

- Process Water Pipes

- White Liquor

- Black Liquor

- Pulp and Slurry Piping

Water & Wastewater

- Raw Sewage Piping

- Prestressed Concrete Cylinder Piping (PCCP)

- Aeration Piping

- High Wear Elbows and pump outlet piping

Mining

- Process Water Pipes

- Fire Suppression

- Slurry Piping

- Leaching Circuit

Power Transmission

- High-Pressure, Fluid-Filled Systems

- High-Pressure, Gas-Filled Systems

- Pipe-Type Cables within Manholes

- Horizontal Directional Drilled Pipes

- Lead Sheathed Feeder Pipes

Power Generation

- Circulating Water Line Repair

- Fire Suppression Systems

- Coal Pipe Elbows

- Flue Gas Desulfurization Piping and Ductwork

- Water Treatment and Condensate Piping

- Natural Gas Pipes

- Prestressed Concrete Cylinder Piping

Our Composite Pipe Repair Solutions

External Pipe Repair

If the pipe is readily accessible from the outside, an external composite pipe repair is probably the best option. External repairs with our Carbon Fiber system are fully compliant with ASME PCC-2 (2018) for both standard and high-risk repairs, even with through-wall corrosion.

Buried Pipe Repair

Pipes above 30 inches in diameter can be repaired internally to completely eliminate the cost of excavation. Our carbon fiber pipe reinforcement systems can either enhance the structural strength of the host pipe or it can be used to build a structurally independent composite pipe within the host pipe.

Active Leak Mitigation

Composite repairs can often be performed on leaking pipes, without taking your process offline or with minimal downtime. Reach out to an expert at Advanced FRP to see if we can help keep you online while providing a long-term composite repair solution for your piping system.

See Us at Work

Have Corroded Pipes? Looking for Carbon Fiber Pipe Repair?

Contact us for a free evaluation!

X